Are you curious to know what is knurling? You have come to the right place as I am going to tell you everything about knurling in a very simple explanation. Without further discussion let’s begin to know what is knurling?

In the world of manufacturing and engineering, precision and functionality are paramount. One technique that adds both practicality and visual appeal to various objects is knurling. In this blog post, we will delve into what knurling is, its purpose, the process involved, and its applications across different industries.

What Is Knurling?

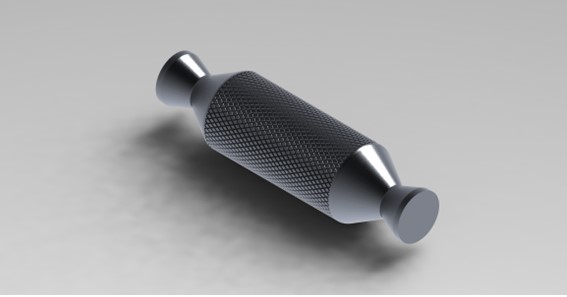

Knurling is a manufacturing process used to create a pattern of ridges or grooves on the surface of a material, typically metal. These ridges, known as knurls, provide improved grip, allowing for better handling and manipulation of objects. Knurling serves both functional and aesthetic purposes, offering increased traction while adding visual interest to a wide range of products.

The Process Of Knurling

The knurling process involves pressing a knurling tool onto the surface of the workpiece to create the desired pattern. The tool consists of two hardened, roller-like dies with complementary knurled patterns engraved on their surfaces. These dies are pressed against the workpiece using a lathe or a knurling tool, causing the material to deform and form the knurled pattern.

There Are Two Main Types Of Knurling Patterns:

- Diamond Knurling: Diamond knurling is the most common type of knurling pattern. It features a series of diamond-shaped ridges or points, with each ridge intersecting at a 45-degree angle. This pattern provides a firm grip and is often used on tools, handles, knobs, and other objects where enhanced traction is essential.

- Straight Knurling: Straight knurling consists of parallel ridges or straight lines running along the surface of the material. This pattern is suitable for applications where a linear grip is required, such as on cylindrical objects like shafts, pins, or knobs.

Applications Of Knurling

Knurling finds its application in various industries and products:

- Tools And Machinery: Knurling is commonly used on the handles of hand tools, providing a secure grip for improved control and handling. It can also be found on machine knobs, gears, and levers, allowing operators to easily manipulate and adjust settings.

- Automotive Industry: Knurling is utilized in the automotive industry for applications such as gear shift knobs, steering wheel grips, and pedals. The knurled patterns enhance grip and control, particularly in situations where hands may be wet or slippery.

- Electrical And Electronic Devices: Knurling is often employed in the design of electrical connectors, switches, and control knobs. The textured surface provides tactile feedback and makes it easier to turn or adjust settings.

- Decorative Applications: Beyond its functional benefits, knurling also adds an aesthetic appeal to certain objects. It can be seen in jewelry, writing instruments, decorative hardware, and luxury products, where the knurled patterns enhance the visual and tactile experience.

Conclusion

Knurling is a versatile manufacturing technique that combines functionality and aesthetics. By adding ridges or grooves to the surface of a material, knurling enhances grip, improves handling, and offers a distinctive visual appeal. From tools and machinery to automotive components and decorative items, knurling finds its application across various industries. Next time you handle a knurled object, take a moment to appreciate the precision and craftsmanship that went into creating its functional and visually pleasing knurled surface.

Get to know some more interesting facts on Petsbee

FAQ

What Is The Purpose Of Knurling?

Knurling allows hands or fingers to get a better grip on the knurled object than would be provided by the originally smooth metal surface. Occasionally, the knurled pattern is a series of straight ridges or a helix of “straight” ridges rather than the more-usual criss-cross pattern.

What Are The Three Types Of Knurling?

Three common knurl patterns are: straight, diagonal (left or right-hand), and diamond.

What Are The Two Types Of Knurling?

Cut and form knurling are the two methods of creating knurling. Form knurling is the standard form of knurling. Form knurling is pressing the knurling tool into the workpiece to create the raised grooves or teeth. Cut knurling scrapes away material instead to create the knurling pattern.

What Happens In Knurling?

Knurling is the metal modification process of creating small ridges along a metal object’s surface to improve the ease with which such an object can be physically handled, lifted or gripped.

I Have Covered All The Following Queries And Topics In The Above Article

What Is Knurling On A Barbell

What Is The Purpose Of Knurling

What Is Knurling Process

What Is Knurling?

What Is Knurling On A Punty

What Is Knurling In A Phography Filter Lens

Knurling Tool

Types Of Knurling

Knurling Solidworks

Knurling Machine

Knurling Pronunciation

Knurling Specification

what is knurling

What is the meaning of knurling

What is knurling process?